Buka Izingxenye Ukuhlolwa

Isisekelo senqubo yethu yokukhiqiza ilele ekwakhiweni kwezinga eliphezulu kanye nolwazi oluqoqiwe.Ngeminyaka yobungcweti bokwenza amawashi, sisungule abahlinzeki bempahla eluhlaza abaningi bekhwalithi ephezulu nabaqinile abathobela izindinganiso ze-EU.Lapho kufika izinto zokusetshenziswa, umnyango wethu we-IQC uhlola ngokucophelela ingxenye ngayinye nezinto ezibonakalayo ukuze uphoqelele ukulawulwa kwekhwalithi okuqinile, kuyilapho usebenzisa izinyathelo zokulondoloza ezidingekayo.Siqasha ukuphathwa kwe-5S okuthuthukisiwe, okuvumela ukuphathwa kwempahla yesikhathi sangempela okuphelele nokusebenza kahle kusukela ekuthengeni, irisidi, ekugcinweni, ekukhululweni okulindile, ekuhlolweni, kuye ekukhishweni kokugcina noma ekwenqatshweni.

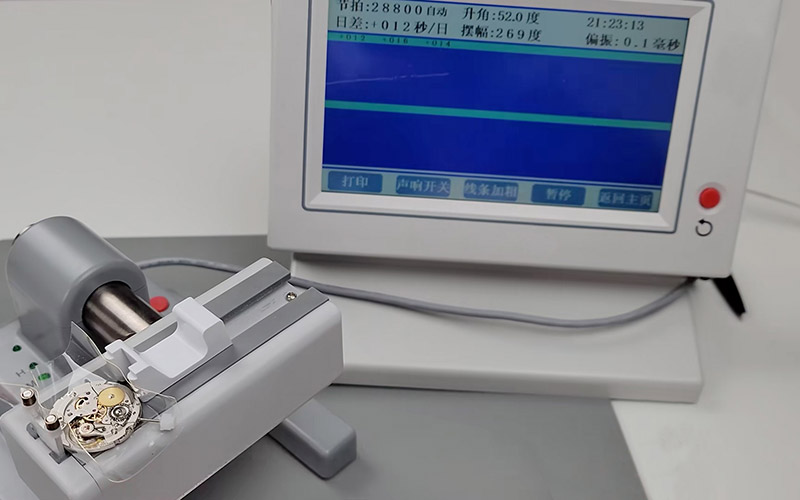

Ukuhlola Ukusebenza

Kuzo zonke izingxenye zewashi ezinemisebenzi ethile, ukuhlolwa kokusebenza kuyenziwa ukuze kuqinisekiswe ukusebenza kwazo okufanele.

Ukuhlolwa Kwekhwalithi Yento

Qinisekisa ukuthi izinto ezisetshenziswa ezingxenyeni zewashi ziyahlangabezana yini nezidingo ezibekiwe, ukuhlunga izinto ezisezingeni eliphansi noma ezingathobeli.Isibonelo, izintambo zesikhumba kufanele zihlolwe umzuzu ongu-1 we-high-intensity torsion test.

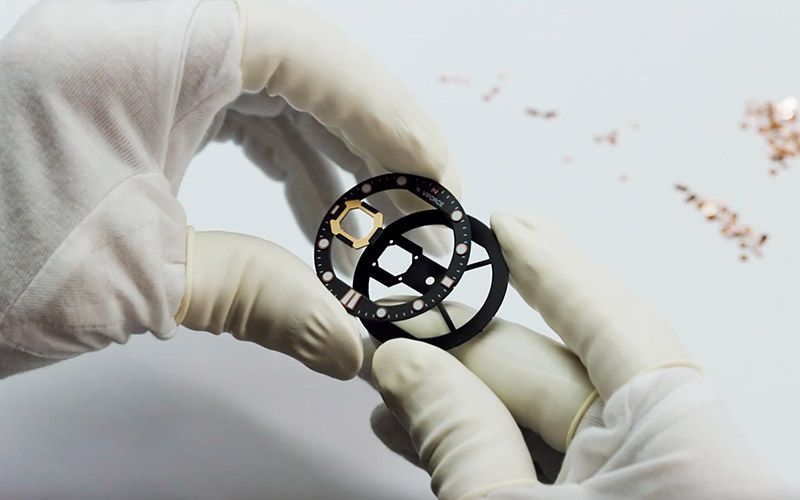

Ukuhlolwa Kwekhwalithi Yokubukeka

Hlola ukubukeka kwezingxenye, okuhlanganisa ikesi, ukudayela, izandla, izikhonkwane, nesongo, ukubona ukushelela, ukucaba, ukuhlanzeka, umehluko wombala, ukujiya kwe-plating, njll., ukuze uqinisekise ukuthi azikho iziphambeko noma umonakalo osobala.

I-Dimensional Tolerance Check

Qinisekisa uma ubukhulu bezingxenye zewashi zihambisana nezidingo zokucaciswa futhi zingena ngaphakathi kwebanga lokubekezelela kobukhulu, okuqinisekisa ukufaneleka kokuhlanganiswa kwewashi.

Ukuhlola Ukuhlangana

Izingxenye zewashi ezihlanganisiwe zidinga ukubhekwa kabusha kokusebenza komhlangano wezingxenye zazo ukuze kuqinisekiswe ukuxhumana okulungile, ukuhlanganisa, nokusebenza.

Madoda

Madoda  Abesifazane

Abesifazane  Abashadile

Abashadile  Iwashi ledijithali

Iwashi ledijithali I-Quartz

I-Quartz I-Quartz

I-Quartz I-Quartz Chronograph Watch

I-Quartz Chronograph Watch  I-Multi-Function Quartz Watch

I-Multi-Function Quartz Watch  Iwashi likaMechanical elizenzakalelayo

Iwashi likaMechanical elizenzakalelayo  Iwashi Elinamandla Elanga

Iwashi Elinamandla Elanga