Watch Parts Inspection

The foundation of our production process lies in top-notch design and accumulated experience. With years of watchmaking expertise, we have established multiple high-quality and stable raw material suppliers that comply with EU standards. Upon arrival of raw materials, our IQC department meticulously inspects each component and material to enforce rigorous quality control, while implementing necessary safety storage measures. We employ advanced 5S management, enabling comprehensive and efficient real-time inventory management from procurement, receipt, storage, pending release, testing, to final release or rejection.

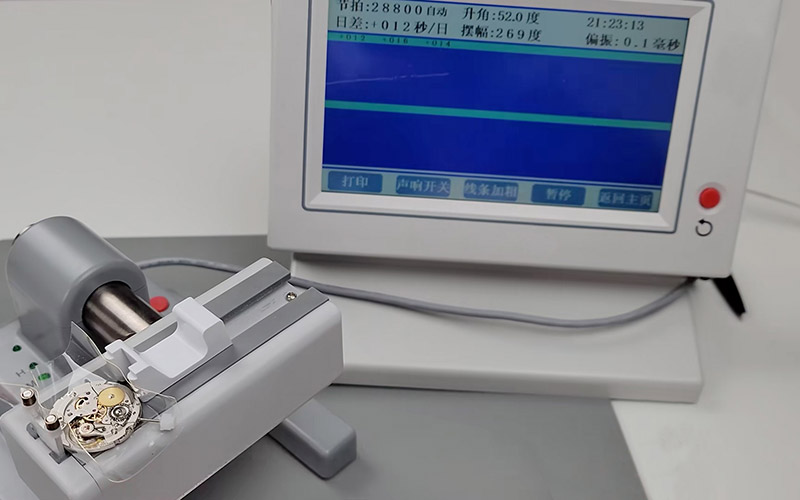

Functionality Testing

For every watch component with specific functions, functional tests are conducted to ensure their proper operation.

Material Quality Testing

Verify if the materials used in watch components meet specification requirements, filtering out substandard or non-compliant materials. For instance, leather straps must undergo a 1-minute high-intensity torsion test.

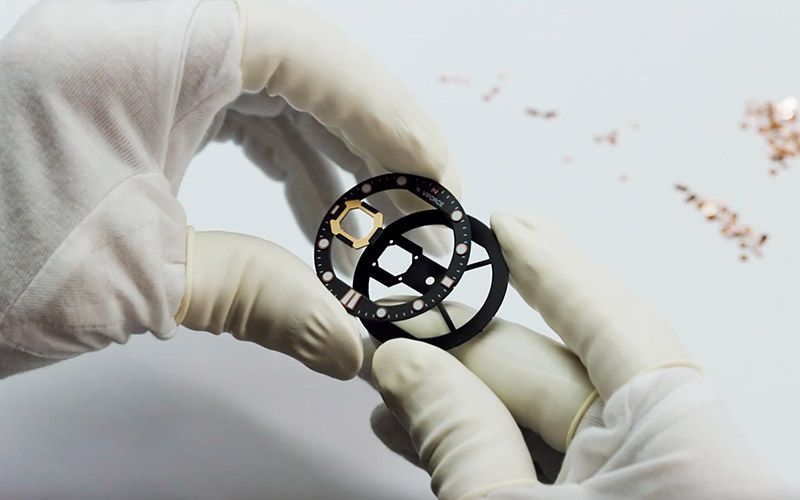

Appearance Quality Inspection

Inspect the appearance of components, including case, dial, hands, pins, and bracelet, for smoothness, flatness, neatness, color difference, plating thickness, etc., to ensure there are no obvious defects or damages.

Dimensional Tolerance Check

Validate if the dimensions of watch components align with specification requirements and fall within the dimensional tolerance range, ensuring suitability for watch assembly.

Assemblability Testing

Assembled watch parts require a recheck of the assembly performance of their components to ensure correct connection, assembly, and operation.

Men

Men

Women

Women

Couples

Couples

Digital Watch

Digital Watch Quartz

Quartz Quartz

Quartz Quartz Chronograph Watch

Quartz Chronograph Watch

Quartz

Quartz Automatic Mechanical Watch

Automatic Mechanical Watch

Solar-Powered Watch

Solar-Powered Watch